Slime Dryer

Product Description of slime dryer:

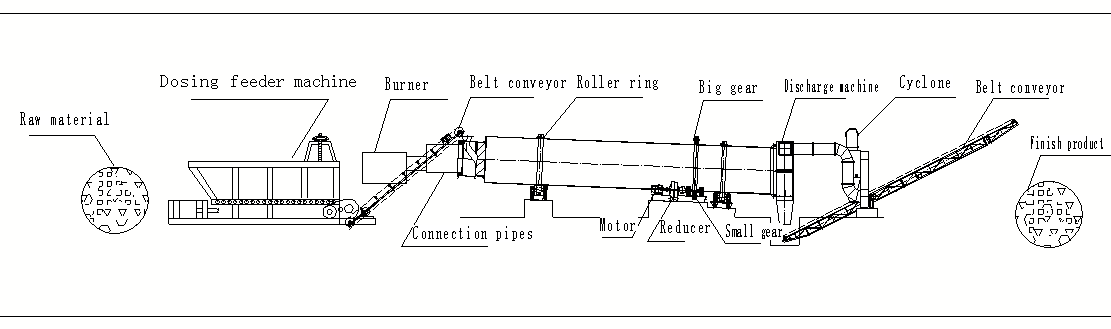

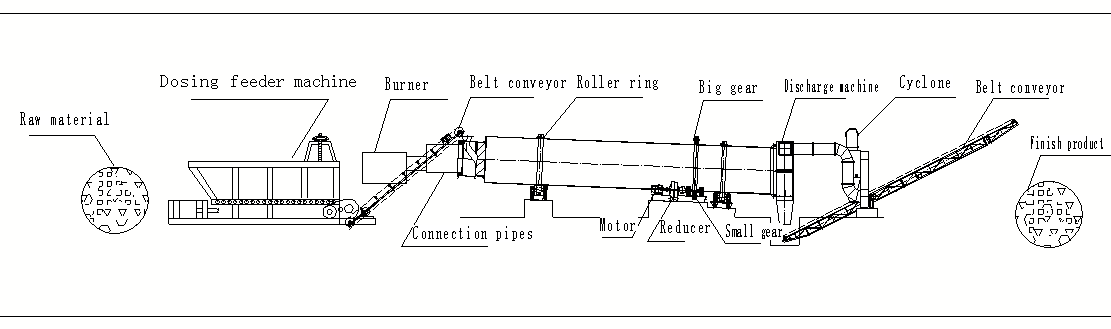

The slime dryer consists of heat source,scattering device, belt feeder, feeding machine, rotary drum, belt discharging machine, induced draft fan (provide roof fan), unloading machine and power distribution cabinet.

The slime dryer consists of heat source,scattering device, belt feeder, feeding machine, rotary drum, belt discharging machine, induced draft fan (provide roof fan), unloading machine and power distribution cabinet.

Working Principle of slime dryer:

The slime has viscosity. There are several working areas after the wet slurry entering into the dryer.

1. Material feeding zone.The wet slime is heated by high-temperature hot air in this area with moisture being rapidly evaporated,and the slime is taken up many times by big lead angle plate, thus there is no hardening happens to the slime.

2. Cleanup area, the wet slime will bond the inner wall easily during being taken up,so the sweeping device will clean up the inner wall timely. At same time, the sweeping device will also crush the hardening material to enlarge the heat exchange area of the slime, improving drying efficiency.

3. Inclined lifting plate, wet slurry material in this area shows a low moisture loose state, no sticking happening, materials after heat exchange enters discharge zone.

4. Discharge zone, there is no stirring board in this area, and materials scroll through this area to the discharge port.

The slime has viscosity. There are several working areas after the wet slurry entering into the dryer.

1. Material feeding zone.The wet slime is heated by high-temperature hot air in this area with moisture being rapidly evaporated,and the slime is taken up many times by big lead angle plate, thus there is no hardening happens to the slime.

2. Cleanup area, the wet slime will bond the inner wall easily during being taken up,so the sweeping device will clean up the inner wall timely. At same time, the sweeping device will also crush the hardening material to enlarge the heat exchange area of the slime, improving drying efficiency.

3. Inclined lifting plate, wet slurry material in this area shows a low moisture loose state, no sticking happening, materials after heat exchange enters discharge zone.

4. Discharge zone, there is no stirring board in this area, and materials scroll through this area to the discharge port.

The Feature of slime dryer:

1. Large production capacity, low fuel consumption, low production cost.

2. Adopt downstream drying, hot air and wet material enter into the dryer on the same side, good high temperature evaporation effect, low temperature in outlet, high thermal efficiency.

3. Set different operating data according to different materials, so that the material in the dryer cylinder body is able to form a stable full-cut material particle curtain to get full heat exchange.

4. Advanced feeding and discharging device, avoiding stuck, discontinue, uneven or material returning of traditional drum dryer, to relieve the load of dust removal system.

5. Advanced internal structure, better cleanup and thermal conductivity to dispersed material to avoid adhesion between material and cylinder wall, good adaption to big water content and sticky materials.

6. This dryer achieves "zero thrust", which greatly reduces the wear and tear strength of block&riding wheel, getting more smooth operation.

7. Use "self-aligning roller-type device", so that the riding and rolling ring have linear contact, thereby greatly reducing the wear and power loss.

8. The particle size and moisture is able to controlled by users. (the slime moisture can be blow 8% and particle size can be controlled within 8mm)

Technical Parameters of slime dryer:

1. Large production capacity, low fuel consumption, low production cost.

2. Adopt downstream drying, hot air and wet material enter into the dryer on the same side, good high temperature evaporation effect, low temperature in outlet, high thermal efficiency.

3. Set different operating data according to different materials, so that the material in the dryer cylinder body is able to form a stable full-cut material particle curtain to get full heat exchange.

4. Advanced feeding and discharging device, avoiding stuck, discontinue, uneven or material returning of traditional drum dryer, to relieve the load of dust removal system.

5. Advanced internal structure, better cleanup and thermal conductivity to dispersed material to avoid adhesion between material and cylinder wall, good adaption to big water content and sticky materials.

6. This dryer achieves "zero thrust", which greatly reduces the wear and tear strength of block&riding wheel, getting more smooth operation.

7. Use "self-aligning roller-type device", so that the riding and rolling ring have linear contact, thereby greatly reducing the wear and power loss.

8. The particle size and moisture is able to controlled by users. (the slime moisture can be blow 8% and particle size can be controlled within 8mm)

Technical Parameters of slime dryer:

|

Model (mm) |

Angularity (°) |

Rotate Speed (r/min) |

Enter Temperature (℃) |

Power (kw) |

Capacity (t/h) |

Weight (t) |

| Ф600x6000 | 3-5 | 3-8 | ≤700 | 3 | 0.5-1.5 | 2.9 |

| Ф800x8000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.0 | 3.5 |

| Ф800x10000 | 3-5 | 3-8 | ≤700 | 4 | 0.8-2.5 | 4.5 |

| Ф1000x10000 | 3-5 | 3-8 | ≤700 | 5.5 | 1.0-3.5 | 5.6 |

| Ф1200x10000 | 3-5 | 3-8 | ≤700 | 7.5 | 1.8-5 | 14.5 |

| Ф1200x12000 | 3-5 | 3-8 | ≤700 | 11 | 2-6 | 14.8 |

| Ф1500x12000 | 3-5 | 2-6 | ≤800 | 15 | 3.5-9 | 17.8 |

| Ф1800x12000 | 3-5 | 2-6 | ≤800 | 18 | 5-12 | 25 |

| Ф2200x12000 | 3-5 | 1.5-6 | ≤800 | 18.5 | 6-15 | 33 |

| Ф2200x18000 | 3-5 | 1.5-6 | ≤800 | 22 | 10-18 | 53.8 |

| Ф2200x20000 | 3-5 | 1.5-6 | ≤800 | 30 | 12-20 | 56 |

| Ф2400x20000 | 3-5 | 1.5-5 | ≤800 | 37 | 18-30 | 60 |

| Ф3000x20000 | 3-5 | 1.5-5 | ≤800 | 55 | 25-35 | 78 |

| Ф3000x25000 | 3-5 | 1.5-5 | ≤800 | 75 | 32-40 | 104.9 |

Next: Sand Dryer Previous: Cassava Drying Production Line

Your Contact Details To Us

(*)Required information