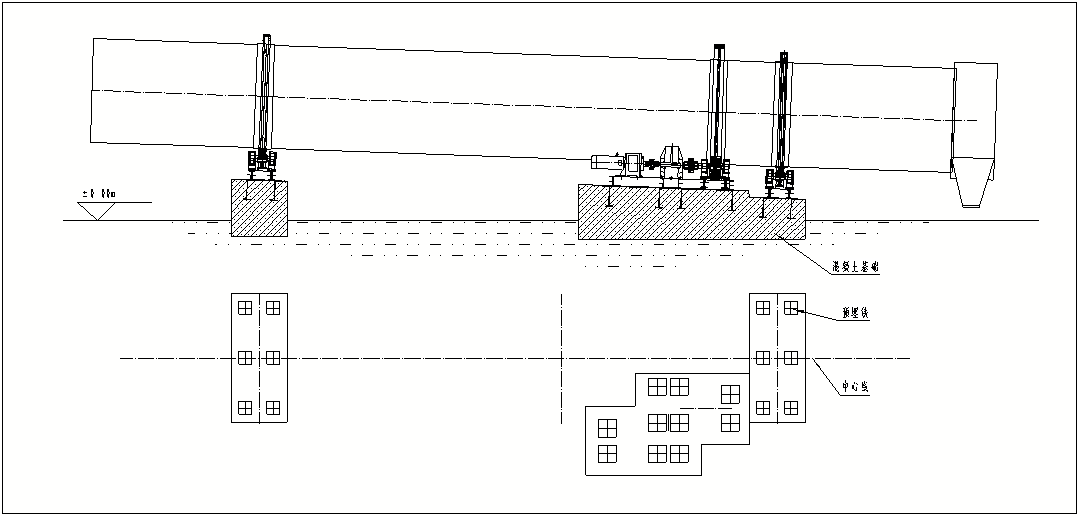

Foundation construct and layout of paper pulp rotary dryer

Foundation is mainly used to fasten the drying equipment .the most important is the to concrete ,fasten the rebar,embedded iron and do the steel etc.

Concrete foundation: it is made by concreting, the foundation is bigger than the carrier roller and transmission parts, slope is 1.5 °-3°it need design according to the drying equipment and the material.for example,the coal,the slope is around 2°, it need design according to the drying equipment and the material.

The exact height depend on the distance of the discharging port and the earth, generally speaking, the distance between the discharging port and the earth>200mm. Concrete drive part basis need according to transmission parts installation and commission center to make sure its final height. It also should pay attention to the angel problems. The concrete foundation should below depth ground elvel, the general depth distance should be in the permafrost blow, so it can make the equipment more stable than the basis before the forming of the concrete foundation be set in the embedded iron, embedded iron inlay fashionable need to check the basis of size whether there is a deviation, the basis of the deviation of not greater than 1 cm above.

Generally it is”J”type,more stable to fasten drying equipment,the specific size can customized according to

the drying equipment.The specific size range between 200*200mm---400*400mm.The specific height need 500-700mm.

It will be insert before the concrete dried,the specific size of insertion depth required embedded iron plane

and cement plane of equal rank,the specific quantity

will be customized according to the foundation building,generally around 22 piece at least.

contact:

Whatsapp:008613592505674

Email:sales@hwdcrusher.com